Impact

Nuclear Industry Performance Challenges

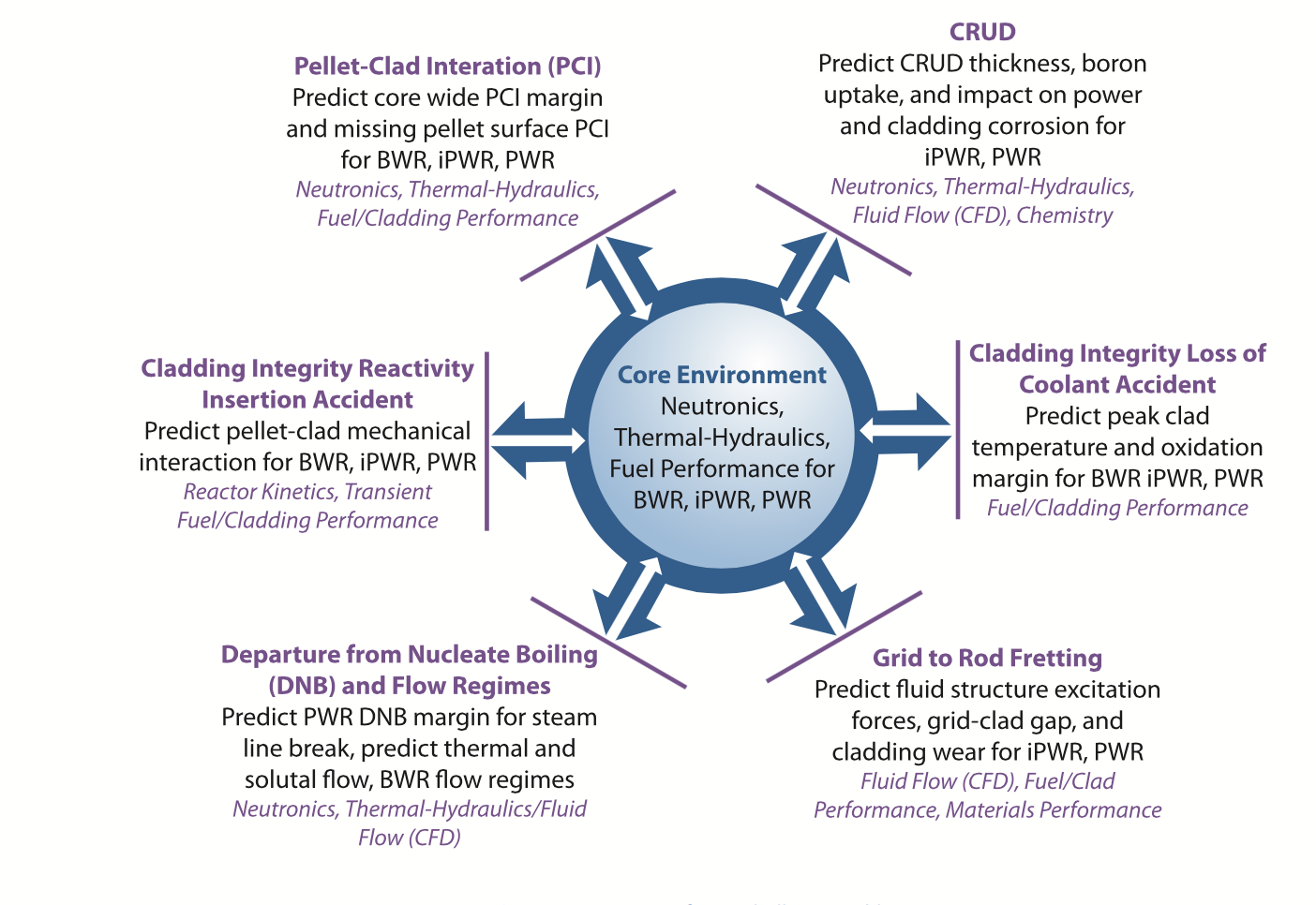

CASL looked 6 key performance challenges the nuclear industry is facing for which advanced modeling and simulation tools could be applied. The challenge problems addressed issues in reactor operation, fuel management, licensing, and materials performance. These issues have a high economic impact on fuel cycle costs, capacity factors, and plant lifetimes where the opportunity in terms of reduced costs and increased revenue are in the hundreds of millions of dollars.

Challenge Problem Success

- VERA provides unprecedented detail assessment of crud growth and crud boron behavior as well as the local and global impacts of crud growth on power and subcooled boiling.

- An advanced Crud Induced Localized Corrosion (CILC) screening capability has been developed within VERA that allows for detailed evaluation of the local fuel corrosion evolution during the fuel cycle.

- VERA results demonstrate a fundamental advancement in CFD two-phase flow modeling and simulation with the ability to include the effect of surface characteristics on the boiling predictions from first principle bases. The ability to predict rod surface effects within two-phase CFD will allow for modeling of rod aging as well as Accident Tolerant Fuel (ATF) concepts.

- Industry applications of the CASL Reactivity Insertion Accident (RIA) modeling and simulation capabilities are expected to be implemented in reference calculations, determination of margins to regulatory figures of merit, evaluation of RIA test results, provision of simulation results to fill gaps in the RIA experimental testing database, and potentially replacement or augmentation of licensing methodologies. Current emerging applications for RIA include ATF and high-enriched and high-burnup fuel.*

- VERA analysis of fuel performance for flexible power operations allows for detailed rod-by-rod analysis performed utilizing coupled core simulation and fuel performance capabilities.**

- The key material and behavior models required to address transient high-temperature phenomena occurring during loss of coolant accidents for PWRs have been implemented

- The completion of the grid to rod fretting challenge problem provides a foundation for analyzing future reactor materials, such as new ATF claddings.

Deployment to Industry

A significant effort was put forth in the final years of CASL to complete work on the CASL challenge problems as well as pivot towards activities to enable broad VERA deployment to industry. Guidance was provided by the CASL Industry Council, Science Council, and Board of Directors to achieve the objectives outlined in the initial CASL proposal and renewal application, as reflected in the following end-state vision for the program:

By the end of the CASL operational period, CASL will have successfully developed and deployed advanced M&S technologies that can be used with confidence to solve the CASL challenge problems and address future nuclear energy industry challenges, emerging issues, and evolving opportunities.

This result was achieved through implementation of an NQA-1 compliant Software Quality Assurance program, development of the VERA Users Group, and commercial licensing and distribution of the VERA code suite.

Industry Use of VERA

VERA applications represent a broad spectrum of design and operating conditions for the current and future operating fleet. The analyses performed represent a key component of the VERA verification and validation plan and assures confidence in the robustness of the software’s physics, geometry, and numerical solvers. Steady-state core follow and startup physics analysis, which confirms reactivity and thermal margin as well as cycle energy production capability is the starting point for all other VERA applications.

The table on the right shows the plant, operating cycles, reactor, and fuel type for which VERA benchmarking was performed. This list represents nearly the full spectrum of PWR reactors and operating fuel designs within the US nuclear fleet as well as the advanced LWR reactor designs, such as the NuScale SMR. The list represents reactors of different sizes, power density, cycle energy production, fuel products, burnable absorbers and core loading pattern design strategies. Note that each plant on the list has different requirements based on energy production requirements, requirements for load follow or coast down, its maintenance and fueling outage schedule, and fuel product transitions (which may impose additional constraints on thermal operating margins).

| Plant | Cycles | Reactor and Fuel Type |

|---|---|---|

| AP1000 | 1-5 | W Gen III+ 2-loop 17×17 XL |

| Byron 1 | 17-21 | W 4-loop 17×17 |

| Callaway | 1-12 | W 4-loop 17×17 |

| Catawba 1 | 1-9 | W 4-loop 17×17 |

| Catawba 2 | 8-22 | W 4-loop 17×17 |

| Davis-Besse | 12-15 | B&W 15×15 |

| Farley | 23-27 | W 3-loop 17×17 |

| Haiyang | 1 | W Gen III+ 2-loop 17×17 XL |

| Krško | 1-3, 24-28 | W 2-loop 16×16 |

| NuScale | 1-8 | SMR |

| Oconee 3 | 25-30 | B&W 15×15 |

| Palo Verde 2 | 1-16 | CE Systems 80 16×16 |

| Sanmen | 1 | W Gen III+ 2-loop 17×17 XL |

| Seabrook | 1-5 | W 4-loop 17×17 |

| Shearon Harris | Surrogate | W 3-loop 17×17 |

| South Texas 2 | 1-8 | W 4-loop 17×17 XL |

| Three Mile Island | 1-10 | B&W 15×15 |

| V.C. Summer | 17-24 | W 3-loop 17×17 |

| Vogtle 1 | 9-15 | W 4-loop 17×17 |

| Watts Bar 1 | 1-18 | W 4-loop 17×17 |

| Watts Bar 2 | 1-2 | W 4-loop 17×17 |